I-silicon ye-Monocrystalline ibhekisa kwi-crystallization yonke yezinto ze-silicon zibe yi-crystal form enye, okwangoku isetyenziswa ngokubanzi izixhobo zokuvelisa amandla e-photovoltaic, i-monocrystalline i-silicon iiseli zelanga zelanga zezona teknoloji zikhulileyo kwiiseli zelanga ze-silicon-based, ngokumalunga ne-polysilicon kunye ne-amorphous silicon iiseli zelanga zelanga, ukuguqulwa kwe-photoelectric ukusebenza kwayo kuphezulu. Ukuveliswa kokusebenza okuphezulu kweeseli ze-silicon ze-monocrystalline zisekwe kumgangatho ophezulu wezinto ze-silicon ze-monocrystalline kunye neteknoloji yokucubungula evuthiweyo.

Iiseli zelanga ze-silicon ze-Monocrystalline zisebenzisa i-monocrystalline silicon iintonga ezinobunyulu obufikelela kwi-99.999% njengezinto ezibonakalayo, eziye zandisa iindleko kwaye kunzima ukuzisebenzisa kwizinga elikhulu. Ukuze kugcinwe iindleko, iimfuno zezinto eziphathekayo zokusetyenziswa kwangoku kweeseli zelanga ze-silicon ze-monocrystalline ziye zahlaziywa, kwaye ezinye zazo zisebenzisa izixhobo zentloko kunye nomsila ezicutshungulwe ngamadivayisi e-semiconductor kunye nenkunkuma ye-silicon ye-monocrystalline, okanye zenziwe zibe yi-monocrystalline silicon iintonga zeeseli zelanga. Itekhnoloji ye-monocrystalline silicon wafer milling yindlela esebenzayo yokunciphisa ilahleko yokukhanya kunye nokuphucula ukusebenza kakuhle kwebhetri.

Ukuze kuncitshiswe iindleko zokuvelisa, iiseli zelanga kunye nezinye izicelo ezisekelwe kumhlaba zisebenzisa i-solar-level monocrystalline rods silicon, kwaye izibonakaliso zokusebenza kwezinto eziphathekayo ziye zakhululeka. Abanye banokusebenzisa izixhobo zentloko kunye nomsila kunye nenkunkuma ye-silicon ye-monocrystalline izixhobo ezicutshungulwa zizixhobo ze-semiconductor ukwenza iintonga ze-silicon ze-monocrystalline kwiiseli zelanga. Intonga ye-silicon ye-monocrystalline inqunywe ibe ngamaqhekeza, ngokubanzi malunga ne-0.3 mm ubukhulu. Emva kokupholisha, ukucocwa kunye nezinye iinkqubo, i-silicon wafer yenziwa ibe yi-silicon wafer ekrwada ukuze iqwalaselwe.

Ukusetyenzwa kweeseli zelanga, okokuqala kuzo zonke kwi-silicon wafer doping kunye nokusabalalisa, i-doping ngokubanzi yokulandelela izixa ze-boron, i-phosphorus, i-antimony njalo njalo. Ukusasazwa kuqhutyelwa kwisithando sokushisa esiphezulu sokushisa okwenziwe ngeetyhubhu ze-quartz. Oku kudala i-P> N isidibaniso kwi-silicon wafer. Emva koko kusetyenziswa indlela yokushicilela isikrini, intlama yesilivere ecolekileyo iprintwa kwi-silicon chip ukwenza umgca wegridi, kwaye emva kokuntywila, i-electrode yangasemva yenziwe, kwaye umphezulu womgca wegridi ugqunywe ngomthombo wokubonisa ukuthintela inani elikhulu leefotoni ukuba lingabonakali kumphezulu ogudileyo we-silicon chip.

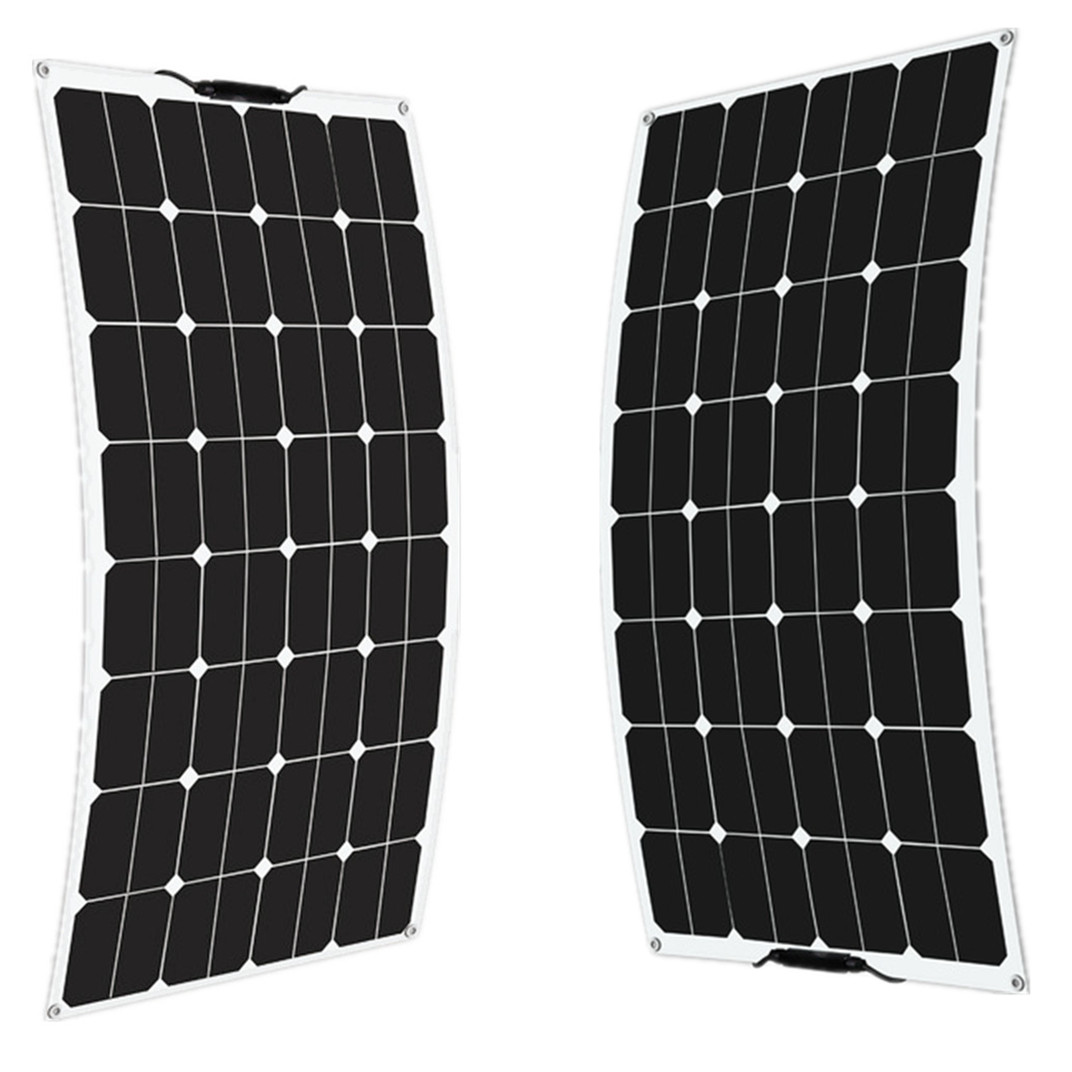

Ngaloo ndlela, ishidi elinye le-monocrystalline i-silicon yeseli yelanga lenziwe. Emva kokuhlolwa okungahleliwe, isiqwenga esisodwa sinokudityaniswa kwimodyuli yeseli yelanga (iphaneli yelanga) ngokweenkcukacha ezifunekayo, kwaye i-voltage ethile yokuphuma kunye nekhoyo yenziwa ngochungechunge kunye neendlela ezifanayo. Ekugqibeleni, isakhelo kunye nezinto eziphathekayo zisetyenziselwa i-encapsulation. Ngokoyilo lwenkqubo, umsebenzisi unokuqamba imodyuli yeeseli zelanga kwiindidi ezahlukeneyo zobungakanani beseli yelanga, eyaziwa ngokuba yi-solar cell array. Ukuguqulwa kwe-photoelectric ukusebenza kakuhle kweeseli zelanga ze-silicon ze-monocrystalline malunga ne-15%, kwaye iziphumo zebhubhoratri zingaphezulu kwe-20%.

Ixesha lokuposa: Sep-07-2023